MANUFACTURING

State of the Art Infrastructure

Water Storage Capacity

Combined tanks hold 50,000 litres of water.

Power Backup

Backup power generator ensures uninterrupted operations during power outages.

Water Filtration System

500 lph R.O and UV filtration system for production water treatment.

Factory Building

R.C.C construction spanning 30,000 sqft.

Fire Safety Measures

Compliance with necessary fire fighting systems.

Controlled Environment

Processing, filling, and raw material storage areas maintained at regulated temperatures.

Sustainable Energy Source

70kw rooftop solar panels contribute to eco- friendly power generation.

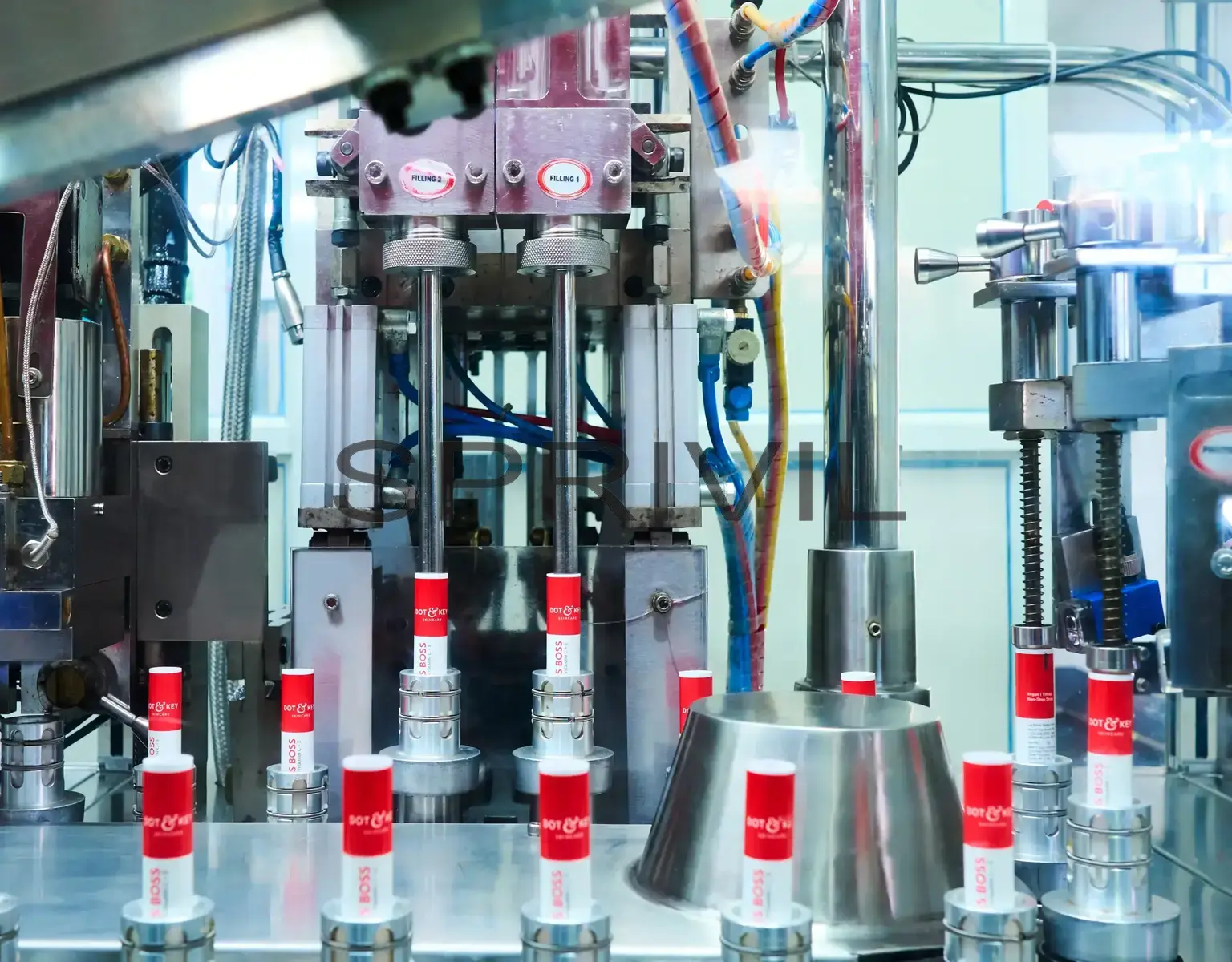

Advanced Manufacturing Machinery

Manufacturing Vessels

Varied capacities ranging from 150 litres to 1500 litres, including jacketed and non-jacketed options.

Filling Machinery

Multiple auto filling machines for round bottles. Machines for flat bottle (front & back) filling and top and bottom filling .

Reputed Manufacturers

Equipment sourced from renowned manufacturers ensuring efficient support for maintenance, spares, change parts, and consumables.

Equipment Material

All manufacturing equipment constructed with S.S. 316 grade steel.

Filling Equipment

Double, four, and six head jar/bottle filling machines. Single and double head tube filling machines for aluminum, laminated, and plastic tubes.

Batch Coding Facilities

Multiple printing and coding machines, including CIJ and TIJ (Continuous Inkjet and Thermal Inkjet).

Equipment and capabilities

GMP approved manufacturing vessels

4.0 Tonnes

Vessel Combined Daily Output Capacity

- Staffed with individuals holding B.Sc. and B.Pharm degrees.

- Proficient in diverse formulations, including emulsions (creams, lotions, etc.), lipsticks, mists, lip balms, and serums.

Leading the Way in Speciality Skincare Manufacturing

Sprivil has established itself as one of India’s top manufacturers of speciality skincare products, known for our expertise in formulating high-quality, efficacious products. Over the past few years, we’ve gained recognition for our ability to create innovative formulations using advanced ingredients, ensuring stability and proven results.

At Sprivil, we’ve worked with over 900 ingredients, including:

Vitamin C (3-O ethyl ascorbic acid), Niacinamide, Retinol, Vitamin E, and more.

AHA, BHA, Salicylic Acid, Hyaluronic Acid, Glycolic Acid, and more.

Botanical extracts and supercritical CO2 extracts.

Ceramides, Peptides, Probiotics, Resveratrol, and Caffeine.

We’ve spent over 2,500 hours in the lab, developing 500 unique formulations. Our extensive work includes manufacturing products for 30 brands, offering everything from hair growth serums to SPF solutions.

Some of our notable products include:

- Hair Growth Serum with Redensyl + Procapil + Bicapil

- Niacinamide + Amino Acid Complex Face Serum

- Retinol + Ceramide Night Repair Cream

- 20% Vitamin C + Ferulic Acid Serum

Our ability to adapt to customer needs, efficiently source materials, and consistently innovate has made us a leader in speciality skincare manufacturing. From customized formulations to full-scale production, we provide brands with top-quality, results-driven products.

Products We Manufacture

Skincare

- Cleansers

- Creams

- Lotions

- Balms

- Scrubs

- Serums

- Masks

- Mists

- Anti-Aging

- Anti-Acne

- Sensitive Skin

Hair Care

- Shampoo

- Conditioner

- Leave In

- Styling

- Scalp

- Hair Growth Serums

Sun Care

- Creams

- Lotions

- Face

- Body

Personal Care

- Lotions

- Creams

- Scrubs

- Cleansers

- Shower & Bath

Filling Capabilities & Labelling Options

- Round bottle/wrap around labelling

- Front and back labelling for flat bottles and tottles

- Shrink tunnel for shrink wrapping

- Tamper proof labelling

- Top and bottom labelling for jars

Tubes

- Plastic, Laminated & Aluminium from 5ml to 200ml | ⌀ 15 to 50mm

Chapsticks

Bottles & Jars

- Glass, Plastic from 5ml to 200ml for viscous & non-viscous products

Tottles & Flat Bottles

Notable Clients